Third-Party Fulfillment: The 3 Benefits for Your Ecommerce Business

Outsourced fulfillment from third-party logistics providers (3PLs) is exploding in popularity, especially in the e-commerce world, because of the cost savings and business improvements they provide. Bringing in professionals to manage this aspect of your business can improve customer relationships, too, making it a smart sales tool.

Let’s look at three of the most significant benefits a 3PL offers, and when those make sense for your operations.

One of the biggest benefits for companies outsourcing their fulfillment is that you can change inventory levels — going up or down — with no need to pay for additional infrastructure.

Warehouse space usually has a limit on how much room you have for new products, shelves, equipment, and people. When you fill all that space, you need to move locations if you want to keep growing.

That can cause delays in growth when you’ve got to wait for a lease to be up, or you’ll face expensive land and construction costs if you’re building a new location. Sometimes, expansion is a risky investment because you have to acquire a significant amount of extra space to grow into, without a guarantee of reaching that volume.

A 3PL can save you on this expense by providing ample warehouse space that gives you room to expand without the structure, land, and staff costs that come with growth. These providers have expansive warehouses designed to meet the needs of multiple growing clients at any one time. And, if they get too big, they pay for expansion instead of you.

Your business might need this 3PL benefit if you can’t reasonably and safely increase inventory levels. If additional products would get in the way of picking, packing, or order accuracy, consider a 3PL. Many companies use third-party fulfillment as a steppingstone between their first warehouse and when they hit the substantial volume that requires an entire professional fulfillment operation of their own.

Third-party fulfillment is built for speed. Their entire business model is about moving inventory and orders as quickly as possible.

For your internal operations, that translates to shorter fulfillment times. Many 3PLs can offer same-day and next-day fulfillment, meaning that orders are picked, packed, and shipped out ASAP. By having a full roster of warehouse staff, a 3PL also can prioritize requests in its systems to meet many expedited delivery demands.

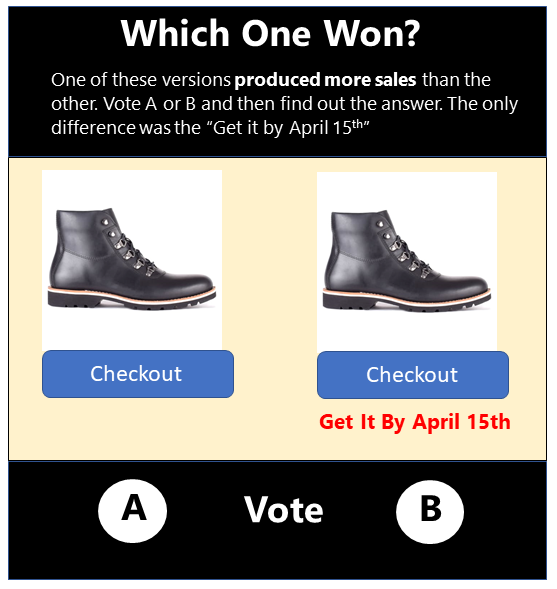

If you're using an order or e-commerce platform that integrates with your 3PL's software, you can even add timers to your website to let customers know that, for example, "orders placed before 5 p.m. are shipped the same day!"

Faster delivery speeds are also available from many 3PLs because of their staff and carrier relationships. By moving high volumes of goods each day, 3PLs can negotiate for cheaper shipping rates than usual. That’s a savings passed on to you and one that you can pass on to customers so they can afford faster shipping.

Leading 3PLs also operate multiple warehouses. This makes locations physically closer to customers, which can speed up delivery times while also reducing delivery costs.

A business like yours can benefit from these 3PL advantages if you're competing in the e-commerce space, where two-day shipping has become the standard. 3PL relationships make this more affordable for you.

Their workforce makes it easier to offer fast shipping for orders placed late in the day because they have carriers come to the 3PL warehouse, instead of needing to send teams to the post office of UPS or FedEx store and meet that location's timetable.

3PLs provide quality control systems designed to improve customer service while protecting costs and inventory. The main way they do this is by monitoring goods in your warehouse and checking them against orders at multiple times during the picking process.

Incorrect orders devour revenue. They lead to increased costs as you pay for goods to be returned and then send out the correct request a second time. A 3PL will help you avoid this by using scanning tools to check inventory as it is unloaded and put on shelves, creating an accurate inventory count.

When an order is received, the picker then uses barcode scanners to scan items as they're picked for a specific order. Packing stations examine the same items and orders to ensure accuracy, so there's less chance of any incorrect package getting out the door. Tracking data also helps them offer advanced inventory planning, so you never have empty shelves.

You get a boost not only from the order accuracy but also from improved customer service. People will be happier and more likely to buy from you again when you get their first order correct.

The best time to use a 3PL for this benefit is when you experience a complaint about orders. If returns are eating into your bottom line, it’s time to try a 3PL.

Jake Rheude is the Director of Marketing at Red Stag Fulfillment, an ecommerce fulfillment warehouse. He has years of experience in ecommerce and business development. In his free time, Jake enjoys reading about business and sharing his own experience with others.